Company History – 190 years and counting

1830 William Waddingtons, wool comb maker

Situated on Albion Street – Silsbridge Lane, now Grattan Road, William Waddington was a manufacturer of wool combs in Bradford the then boom-town of the industrial revolution and wool-capital of the world during the mid-1800’s in a small factory that came to be West End Mills on Richmond Road, Bradford.

1879 Fortune & Bentham

Frank Holdsworth Bentham & Wilson Fortune, two young engineers who had already won their laurels as experts working for W.Waddingtons entered into association to buy the business. With a steady expansion of business, now renamed to Fortune & Bentham, the inventive ingenuity of the partners manifested itself by the construction of special machinery to facilitate speedy production and the out-turn of superior goods, manufacturing combing machines, circles and fallers for the textile industry.

1883 – purchase of W.Bramham & Co

A water lane textile comb making works.

1887 – purchase of John Feather

Comb maker in Keighley.

1888 – move to West End Works

Across the road on the corner of Richmond Road and Longside Lane was a larger site where the company could over the years develop West End Works into what would be their base of operations for the next 70 years.

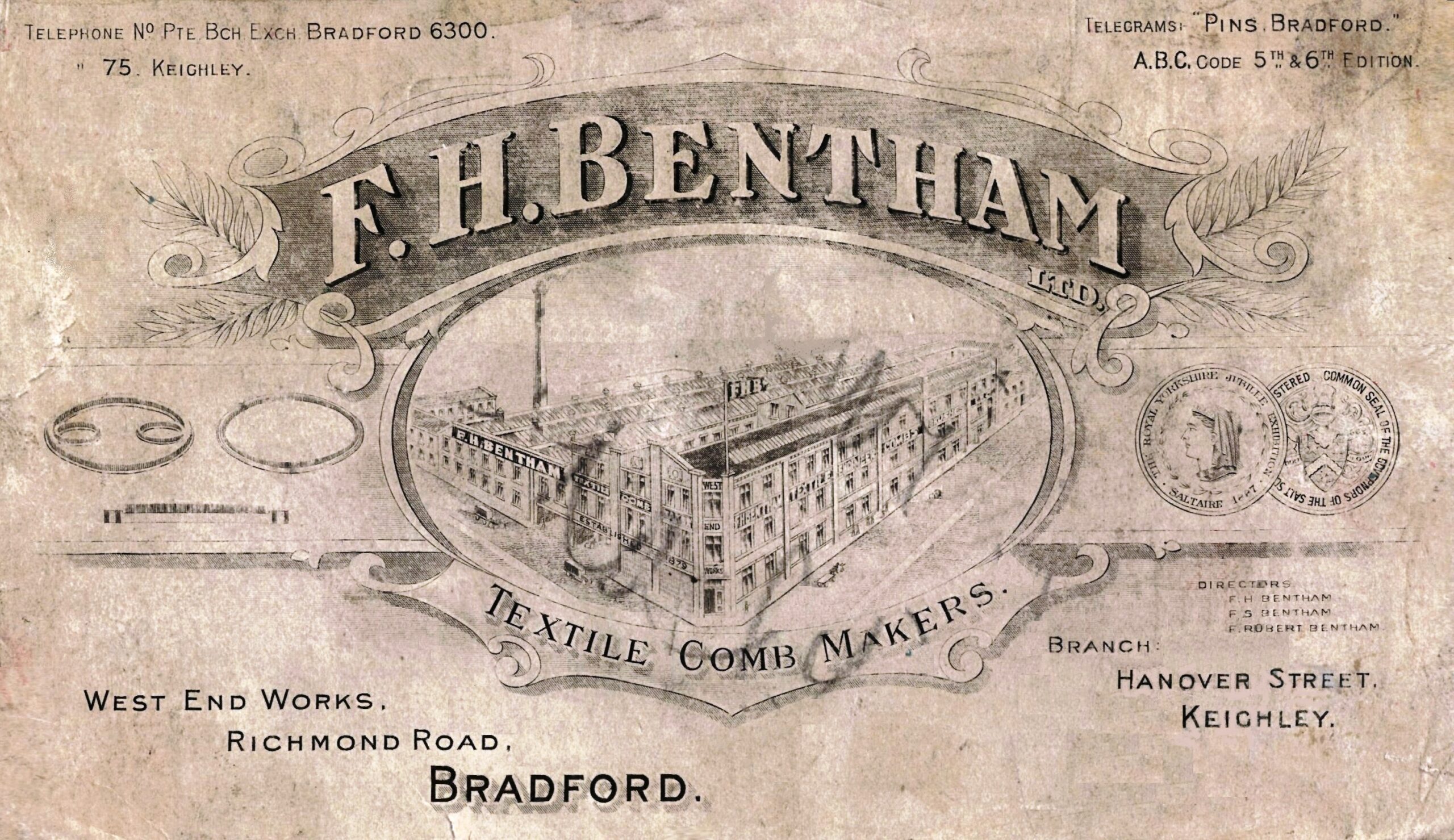

1903 – F.H.Bentham Ltd

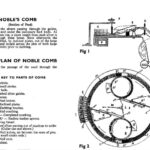

The partnership dissolved with Mr Fortune moving into cycle manufacturing business and F.H. Bentham carrying on with the textile comb making, specialising in the manufacture of the now forgotten Noble Comb and later the French Comb.

1906 – purchase of John Sheard

A wool comb maker of Listerhills Road.

1917 – Keighley expansion

By 1917 the company had grown substantially as F.H.Bentham, expanding to a secondary factory at Hanover Street, Keighley including manufacture of textile brushes.

1932 – purchase of Harry Thompson

A textile brush maker of Rawson Road.

1941 – tyre remoulding

Then in its infancy as an industry, Benthams branched into the manufacture of buffing rasps, later extended to include complete design and manufacture of other machinery and equipment used in the re-moulding industry.

1958 – Bentham Tyre Machinery Co. Ltd (BTYM)

Still under the direction of the Bentham family, Philip & Frank Bentham, by 1958 the section of the company manufacturing equipment for the tyre re-moulding industry had developed to such an extent that a subsidiary company was formed at the company’s newest quarters in Lane Close Mills until 1960 when BTYM Co finally moved to Dotcliffe Mill in Kelbrook, near Barnoldswick under the title of Benthams Press Division.

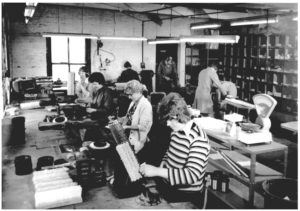

1961 – move to Prospect Works

Following the realisation of the city’s new ring road scheme through the Richmond Road Site the company made the decision to move to Prospect Works Allerton, a spinning mill originally built in 1850, the second oldest mill in Allerton overlooking Ladyhill Park where the company still resides to this day. Thanks to several developments on the site the new premises would provide three time more work space than at the previously limited West End Works.

1973 – Widdop de Courcy

Expanding the companies interests in specialised industrial brush manufacture, Benthams purchased Charles Widdops, a leading producer of hand-drawn brushes, and F. DeCourcy a specialist strip brush manufacturer to form the subsidiary Widdop de Courcy, now known as Widdops Brush. Also based in Prospect Works Bradford, with both companies working hand in hand to provide a wide range of specialist products for various industries.

1975 – Bentham & Holroyd

Under the new directorship of Kenneth Christie, Ken Hudson, Lyndon Nash & Don Barker, all former employees under the Bentham family, the company bought Moses Holroyd engineering and rebranded as Bentham & Holroyd, further diversifying into the manufacture of critical components in the oil and gas industry.

2023 – Post-COVID & Brexit After celebrating 190 years of UK manufacturing in Bradford, we now see ourselves having operated throughout out the global Covid19 Pandemic, supplying to essential industries whilst embracing our situation post Brexit, further diversifying our CNC capabilities and with redevelopments to the Prospect Works premises taking us into 2023 and forwards.